Description

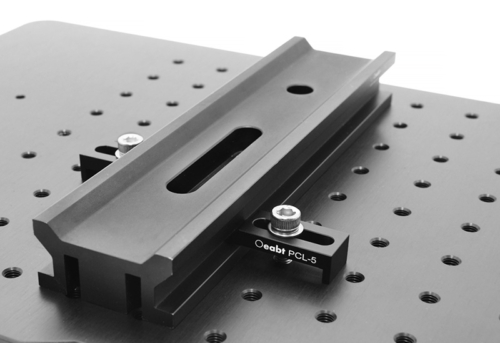

Product Description

- High repeatability for inserting and removing components;

- Ball and V-groove design enables precise alignment;

- The tabletop features a multi-screw hole array for easy component installation;

- Multiple sizes available;

The mounting base is ideal for mounting components that need to be inserted into and removed from the optical path while ensuring high repeatability. The detachable top plate can be magnetically coupled with the bottom base plate.

| Model | MB25 | MB50 | MB75 |

| Specification | 25.0*25.0*12.7mm | 50.0*50.0*25.0mm | 75.0*75.0*25.0mm |

| Top Plate Screw Holes | 1 M4 counterbore | 4 M4 holes, 4 M6 holes, 1 M6 counterbore | 9 M6 holes, 1 M6 counterbore, 2 slots (Ø6.5*30.5mm) |

| Bottom Plate Screw Holes | 1 M4 counterbore | 1 M6 counterbore | 1 M6 counterbore, 2 slots (Ø6.5*30.5mm) |

| Adsorption Force | 3.5lbs | 5lbs | 6.5lbs |

| Weight | 21.8g | 168.4g | 306.4g |

| Material | Aluminum Alloy + Magnet | Aluminum Alloy + Magnet | Aluminum Alloy + Magnet |

Technical Description

(1) The mounting base is well-suited for mounting components that require insertion into and removal from the optical path with high repeatability. The detachable top plate can be magnetically coupled to the bottom base plate, eliminating the need for alignment when reinserting optical elements into the device.

(2) The multi-screw hole array on the mounting base’s tabletop can be used to install connecting rod components. The top plate and bottom base plate are connected by two pairs of strong magnets and make contact with the bottom base plate at three points. Each contact point is a ball bearing on the mounting frame, allowing for highly precise and repeatable insertion and removal.

Assembly

Application Examples