Description

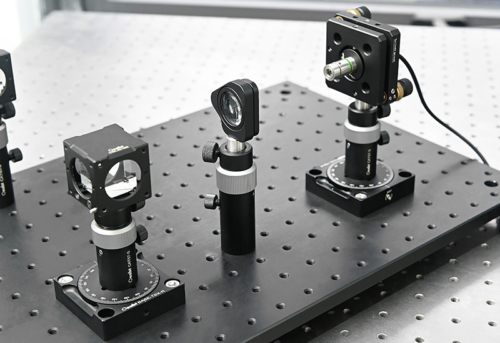

Product Description

- Mounts 1-inch elliptical optical components at a 45° angle relative to the optical axis.

- 8 Ø6mm smooth holes for installing PCM-S series cage rods.

- Provides ±4° pitch and yaw adjustment.

- Z-axis translation of ±3mm achievable using all three adjusters.

- Compatible with 30mm cage systems.

- M4/M6 threaded holes on the sides for installing Ø12mm or Ø1-inch rods.

- Offers a larger clear aperture for transmitted light compared to right-angle mounts for circular lenses.

The right-angle adjustment mount provides pitch and yaw adjustment for 1-inch (minor axis 25.4mm) elliptical optical components fixed in the mounting plate. The elliptical optical components are mounted at a 45° angle relative to the optical axis.

| Specifications | Cage-Style Right-Angle Adjustment Mount |

| Model | KCD1L-EC |

| Dimensions | 48.3*48.3*48.6mm |

| Port Aperture | SM1 threaded ports |

| Adjustment Range | ±4° pitch and yaw |

| Through Hole Spacing | Ø6.02mm, 30mm*30mm |

| Weight | 131.4g |

| Material | 7075 aluminum alloy |

Technical Description

Optical Knowledge Point: Common Optical Thread Size Standards

This is a thread specific to Thorlabs Inc. (USA) and not a commonly used optical thread. “SM” is the code for sewing machine threads in thread notation, but this American company uses it for internal and external thread connections of optical lenses and sleeves. The thread type is UNS (Unified National Special Thread) with a tolerance class of 2A/2B. A unique feature of this thread is that regardless of the diameter, the pitch is 40 threads per inch (TPI). Specific dimensions are as follows:

| Series | Type | Thread (in) | Nominal Diameter (mm) | Minor Diameter (mm) | Pitch Diameter (mm) | Major Diameter (mm) |

| SM05 | Internal | 0.535-40 | 13.59 | 12.98±0.07 | 13.24±0.05 | >13.59 |

| SM05 | External | 0.535-40 | 13.59 | <12.78 | 13.10±0.05 | 13.50±0.05 |

| SM1 | Internal | 1.535-40 | 26.29 | 25.68±0.07 | 25.95±0.05 | >26.29 |

| SM1 | External | 1.535-40 | 26.29 | <25.48 | 25.79±0.05 | 26.19±0.06 |

| SM2 | Internal | 2.535-40 | 51.69 | 51.08±0.075 | 51.35±0.075 | >51.69 |

| SM2 | External | 2.535-40 | 51.69 | <50.87 | 51.18±0.05 | 51.59±0.05 |

Product Description

The right-angle adjustment mount provides pitch and yaw adjustment for 1-inch (minor axis 25.4mm) elliptical optical components fixed in the mounting plate. The adjustable pitch and tilt plates on these cubes are actuated by three 100 TPI (Threads per Inch) adjustment screws, enabling smooth, high-resolution movement. Two of the adjusters are equipped with removable knobs, while the third must be adjusted using a 2mm hex wrench or ball-head screwdriver.

The clips on the mounting plate are used to fix 1-inch (minor axis 25.4mm) elliptical optical components. Tighten the screws to secure the clips above the elliptical lens. The rear-loading design ensures that the installed optical components can be operated even when the mount is equipped with cage rods or lens sleeves. These mounts are designed for installing optical components with a thickness of 4-10mm.

The KCD1L series is designed for mounting Ø1-inch circular and elliptical optical components. Since the mounting plate is at a 45° angle to the standard horizontal position, the hole features a relief cut, providing the maximum clear aperture for any transmitted light and space for operating the installed optical components. The difference between elliptical and circular clear apertures: mounts with elliptical optical components offer a larger clear aperture, while Ø1-inch circular lenses only provide approximately half the clear aperture.

The ports are equipped with SM1 (1.035”-40) threaded holes and 4 Ø6mm smooth holes (6.3mm deep), whose spacing matches the standard of our 30mm cage systems. Cage rods can be fixed using a 2mm hex wrench or ball-head screwdriver via the set screws on the sides of the mount. This design allows direct connection of multiple 30mm cage components.

Each side is equipped with one M4/M6 threaded hole for installing Ø12mm rods and Ø1-inch rods, suitable for free-space setups.

Assembly

Application Example

Engineering Drawing Download