Description

Product Description

- Ø1.5-inch, solid non-magnetic stainless steel construction.

- Suitable for large rigid 3D structures.

- M6 threaded holes at both upper and lower ends.

- Central Ø6mm through hole for sufficient torque during tightening.

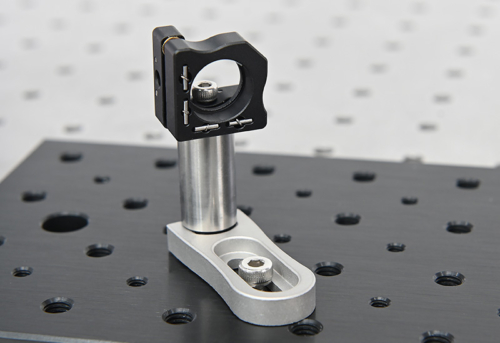

The CFEP-S series Ø1.5-inch rods are available in various heights and can be stacked with each other. This product line includes a range of basic building blocks for assembling large rigid 3D structures. As the most fundamental structural components, they can fix a variety of accessories. The end faces of these solid stainless steel rods, rod spacers, and rod bases are designed with large-diameter undercut grooves, ensuring excellent strength and rigidity.

Technical Description

The CFEP-S series Ø1.5-inch rods are available in various heights for assembling large rigid 3D structures. They can be stacked with each other, and the M6 threaded holes at the center of both ends have a thread depth of 10.5mm, allowing connecting multiple rods to achieve a specific length. Passing a hex wrench through the Ø6mm through hole on the side provides sufficient torque to tighten the stacked rods.

The rod clamps are compatible with our Ø1.5-inch rods. The clamp device on the back can slide on the Ø1.5-inch rod to achieve vertical positioning. Once the desired vertical position is reached, it can be fixed with the quick-release handle on the side. In more compact experimental environments, the handle can be replaced with an M6 cap screw. The handle includes an M6 bolt and can be installed by directly rotating the handle. The internal ratchet drive mechanism prevents the handle from driving the bolt during the return stroke.

The CFP-A1.5 front panel is equipped with 13 M6 threaded holes, which can mount a section of cage system or optical system components on the panel. The CFP-B1.5 allows optical component mounts with M4 threaded holes to be installed on the clamp, and the mount is fixed in position by rotating the knurled knob.

The PSHAM adjustable collar provides an 8.0mm vertical lifting height adjustment stroke for components mounted on the rod. The easy-to-operate drive ring enables fine height adjustment of 0.6mm per rotation.

Installation method: Place the collar on the Ø1.5-inch rod and hold it at the desired height. Use a 5mm hex wrench to tighten the cap screw on the side to fix the position of the collar. Place a set of optomechanical components above the rod collar and rotate the drive ring to adjust the height of the components. After confirming the position, tighten the set screw on the collar wall to lock the height.(When adjusting the height, the nylon ring on the top of the collar can prevent damage to the components.)

The CFEP-B-S rod base can fix the rod to a breadboard or optical platform. The center of the base is equipped with an M6 threaded hole for connecting to the Ø1.5-inch rod. It also has 4 counterbore slots, providing more freedom when fixing to the breadboard and facilitating the selection of the most suitable mounting holes.

Assembly

Application Example

The CFEP-S series Ø1.5-inch rods are available in various heights and can be stacked with each other. This product line includes a range of basic building blocks for assembling large rigid 3D structures.

Engineering Drawing Download