Description

Product Description

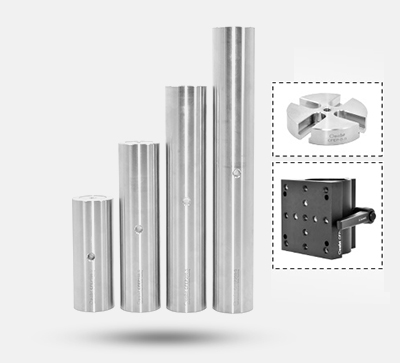

- Elevating rod holders, compatible with Ø12-12.7mm stainless steel rods.

- Adjustable lifting height of 8mm or 12mm via rotating the drive ring.

- The drive adjustment ring moves 0.5mm per full rotation.

- Optional bottom mounting holes: threaded holes or counterbores.

When connecting multiple components on a single optical axis, the CAT-T series’ central threaded connection may cause inconsistent contact directions of the set screws on the side of the rod holder body, leading to deviations in the optical axis path. The CAT-S series avoids this issue—its counterbore design allows users to fix the rod direction by tightening the cap screws downward from the top.

| Model | CAT57-T | CAT57-S | CAT80-T | CAT80-S |

| Dimensions | Ø25*57mm | Ø25*57mm | Ø25*80mm | Ø25*80mm |

| Adjustable Height | 8mm | 8mm | 12mm | 12mm |

| Thread Type | M6 threaded hole | Ø6.05mm counterbore | M6 threaded hole | Ø6.05mm counterbore |

| Weight | 61.8g | 61.1g | 84.5g | 83.6g |

| Material | 7075 aluminum alloy | 7075 aluminum alloy | 7075 aluminum alloy | 7075 aluminum alloy |

Technical Description

The CAT series telescopic rod holders are adjustable and compatible with Ø12mm series stainless steel rods. They are ideal for installing optical components when the exact height of the setup is not determined. The knurled adjustment ring enables a height adjustment range of 8mm/12mm, providing 0.5mm of adjustment per full rotation.

The holder has a square notch inside, providing dual-line contact with the rod for stable rod installation. The entire holder assembly can be locked via the thumb screw at the lower position and the locking hex groove on the thumb screw at the upper position.The built-in screw of the upper thumb screw can be further tightened with a 1.5mm hex wrench. The recommended maximum torque does not exceed 3.2N.m (torque refers to the tendency of a force to rotate an object around a rotating shaft or fulcrum, also known as rotational torque).

The holder is fixed to optomechanical components or breadboards via M6 threaded holes or counterbores at the bottom. For applications requiring fixed direction or coaxial alignment, the CAT-S series with counterbores is recommended.

Assembly

Application Example

Engineering Drawing Download