Have you ever wondered how does your phone’s Face ID accurately recognizes your face, how does a robot vacuum nimbly avoids table and chair legs, how does a factory precisely detect tiny defects in parts? Behind all these applications lies a key device: the speckle laser projector. The seemingly chaotic random light spots it produces are actually “optical codes” carrying precise information, quietly powering advancements in daily life, industry, and healthcare.

- What is a Speckle Laser Projector?

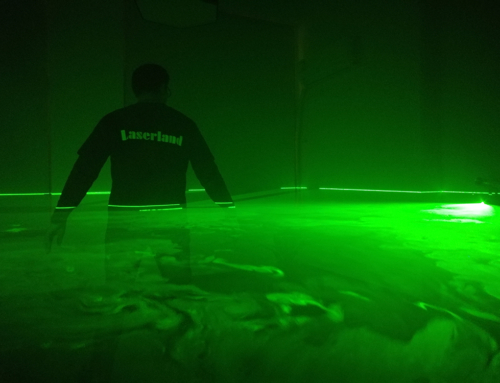

In simple terms, a laser speckle projector is an optical device that generates a random pattern of bright and dark spots (known as “speckles”). These speckles are not not chaotic; they are unique patterns formed by the interference of light when a laser passes through special components like Diffraction Optical Elements (DOE) or ground glass, or when it illuminates a rough surface. These patterns do not intersect or overlap. When projected onto objects at different distances, the pattern changes uniquely—like an “optical fingerprint.”

Compared to traditional light sources, speckle laser projectors have two key advantages:

- They don’t require custom, specialized image sensor chips; ordinary CMOS chips can clearly capture the speckle pattern.

- Upgrade Precision Easily: Using Light Coding technology, precision can be significantly improved simply by increasing the number of speckle points (from 1,000 to 50,000 points), a far more efficient approach than traditional triangulation methods.

In terms of classification, speckle pattern laser projectors can be divided into 6 major categories by point count: 1k, 3k, 5k, 10k, 30k, and 50k points. They can also be categorized by wavelength, such as 830nm infrared lasers and 450nm blue lasers, with different types suited for different application needs. Among these, speckle projectors equipped with DOE (Diffraction Optical Elements) are the most widely used. They can accurately generate the required random dot matrix and are core devices in scenarios like facial recognition and 3D scanning.

- The “Invisible Helper” in Daily Life

Laser speckle projectors are already deeply integrated into our daily lives.

- Consumer Electronics:They act as “security guards” for facial recognition. In smartphones (e.g., Face ID) and smart door locks, an 830nm infrared speckle projector projects tens of thousands of speckle points onto your face. By capturing the 3D distribution of these points, the system quickly builds a facial model—accurate even in low light and resistant to spoofing by photos or videos. These projectors can be as small as 3mm × 3mm, making them ideal for portable devices.

- Smart Home Devices: They serve as the “eyes” for robot vacuum cleaners. A 1,000-point speckle projector continuously projects patterns onto the floor ahead. By analyzing changes in the reflected points, the robot identifies obstacles like furniture, wires, or stairs in real time, enabling safe and efficient cleaning.

- Cultural Heritage: They act as “digital brushes” for artifact restoration. Artists and conservators use speckle projectors to scan cultural relics and artworks. By projecting high-density speckles and capturing 3D data, they create precise digital models, preserving heritage for future generations.

- The “Precision Tool” in Industry and Technology

In industrial and scientific fields, the high precision of speckle projectors is fully utilized, making them core tools for quality control and precision measurement.

- Industrial 3D Scanning:The 50,000-point high-spec speckle projector is an “inverse engineering marvel.” Whether scanning automotive parts, aerospace components, or large machinery, it rapidly captures 3D data by projecting high-density speckles. This supports product design, quality inspection, and reverse engineering. For example, in automotive manufacturing, it detects tiny welding defects; in aerospace, it monitors structural deformations in real time, ensuring flight safety.

- Precision Measurement:It captures “micron-level changes.” From measuring the thickness of transparent materials and the linear expansion coefficient of glass to detecting surface cracks in metals, speckle projectors handle diverse tasks. As early as 1984, they were used to measure surface cracks in bent plates.

- Custom Manufacturing:It enables personalized production. In dental scanning, 5,000+ point projectors capture tooth shapes to support denture design and orthodontics. In industrial part processing, 3D modeling with speckles ensures precise custom manufacturing of complex components.

- The “Non-Invasive Pioneer” in Healthcare

Beyond daily life and industry, speckle laser projectors have opened new application scenarios in biomedical fields. Leveraging their “non-invasive” advantage, they provide novel methods for medical diagnosis.

- Blood Flow Monitoring:Laser Speckle Contrast Imaging (LSCI) technology acts as a “microcirculation detector”. By analyzing the ‘flickering’ changes of speckles on the surfaces of living tissues(e.g., skin, retina, brain), it can non-invasively monitor blood flow velocity and distribution within tissues. This can assist in diagnosing skin conditions like psoriasis and diabetic foot, reflect neural activity in brain function imaging, and even monitor tissue blood supply in real-time during organ transplant surgeries to prevent ischemic injury.

- Tissue Morphology Analysis:It serves as a ‘3D reconstruction tool.’ Performing high-resolution 3D scans of skin or organ surfaces generates 3D models, providing precise references for pathological analysis and surgical planning in procedures like plastic surgery, making medical interventions more targeted.

From the convenience of daily life, speckle laser projectors are writing the story of ‘light dots changing the world’ across multiple domains with their unique technological advantages. As technology continues to advance, this black tech hidden within “random light dots” will unlock even more application scenarios, bringing further surprises to our lives.