A problem often faced in the field of large-scale industrial manufacturing is: how to realize processing positioning conveniently, quickly and accurately? With the development of laser projection technology, positioning achieved through laser projection has begun to be used in the field of industrial manufacturing.

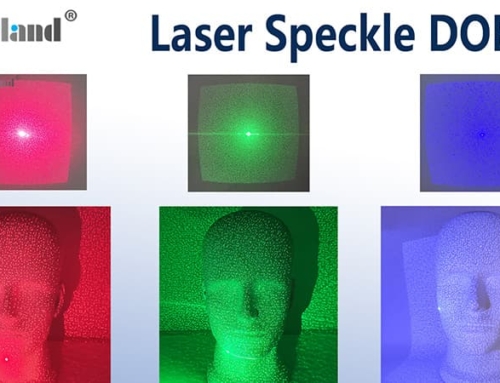

Industrial laser projection positioning is a marking technology that uses laser beams for precise positioning. It usually uses a laser to emit laser spots of different shapes onto the surface of the workpiece, and uses the position and shape of the spot to assist in the measurement and positioning of the position, direction and size of the workpiece.

Industrial laser projection can achieve precise positioning of workpiece surfaces. It determines the position and direction of the workpiece by projecting a laser spot onto the surface of the workpiece, thereby achieving precise positioning operations; in industrial production lines, laser projection positioning can be used for precise assembly of parts. By projecting a laser spot, it indicates the correct position and installation direction of the part; during the manufacturing process, it can monitor the size, shape and position of the workpiece in real time, thereby controlling the processing process and ensuring that the product meets the specifications.

There are many types of lasers used for projection positioning. For example, a line laser is a simple straight line, and the line diameter can be thick or thin, long or short; a cross-line laser is a line that crosses each other perpendicularly; multiple parallel line lasers It is a plurality of straight lines that are parallel to each other at fixed intervals; the ring laser is a single ring, or it can be multiple rings that shrink in equal proportions towards the center; the sight laser is a laser with a crosshair nested in the ring; framing A frame laser is a laser with a crosshair embedded in a square, etc.