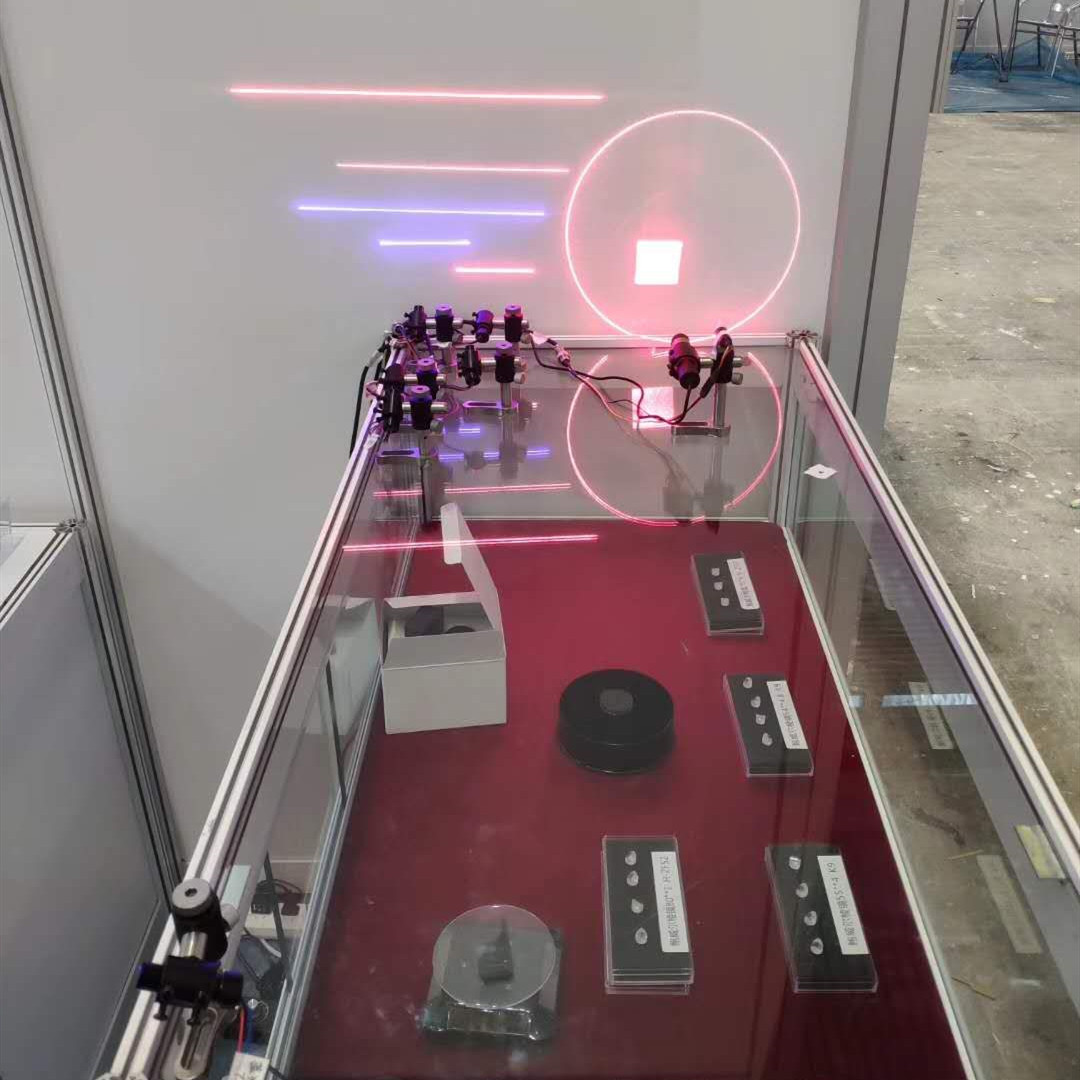

What is Machine Vision?

Machine Vision or Visual inspection is to use a machine to replace the human eye for measurement and judgment. Visual inspection refers to the conversion of the captured object into an image signal by machine vision products (that is, image pickup devices, divided into CMOS and CCD), which is sent to a dedicated image processing system. According to the pixel distribution and brightness, color and other information, it is converted into digitized signals; the image system performs various operations on these signals to extract the characteristics of the target, and then controls the actions of the equipment on the spot according to the results of the discrimination. It is a valuable mechanism for production, assembly or packaging. It has invaluable value in the function of detecting defects and preventing defective products from being delivered to consumers.

What Can Machine Vision Do?

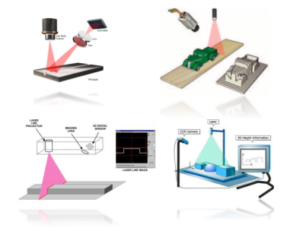

All applications related to machine vision, such as: railway inspection, highway inspection, steel inspection, PCB inspection, 3D inspection, etc. Machine vision lasers provide imaging-based automatic inspection and analysis for such applications as process control, automatic inspection, industrial inspection and robot guidance in industry. In so doing, improvements in products quality, processes efficiency and safety are achieved.

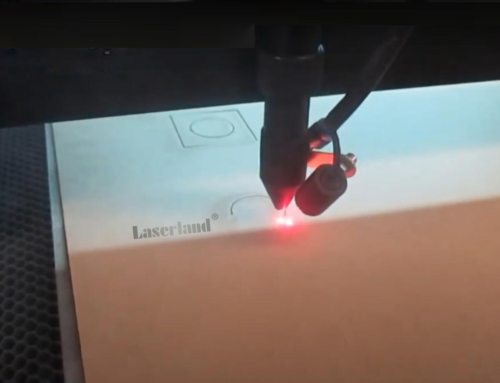

What Does Laser Module Do in Machine Vision?

Some customized structured of laser light for example laser line or other patterns can be used to detect non-conforming parts. Light images that are reflected are analyzed with data collected by image processing systems identifying possible defects.

What kind of laser line generator module can be used in machine vision?

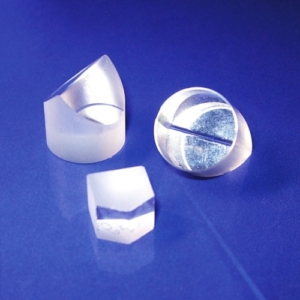

Line laser generator module with powell lens can make a range of uniform intensity of laser lines. Several often applied laser are 405nm, 450nm, 520nm, 532nm, 635nm 808nm or 980nm etc. These green, red, blue, or infrared laser modues use laser diodes as its light source. Nowdays, laser diodes can work stablely and long time meet all the requirements machine vision industry need.

5-110° fan angel are available by applying different powell lens which make uniform lines Have a homogeneous power distribution makes them ideal for machine vision and image processing applications by providing an accurate, highly visible line laser without any ‘noise’ associated with standard line generators.

Laserland laser modules can also be customized into other shapes of lasers, such as circularized dots or elliptical dots, cross-hairs or other customized shapes with customized DOE(Diffraction Optical Elements).

What kind of laser shape can Laserland customize?

1.Dot, circular dot, or elliptical dot

2.Line, 5°, 30°, 45°, 60°, 90°, 110° fan angel

Laser module with uniform laser line has to be equipped with Powell Line Lens

3.Cross-hair, 5°, 30°, 45°, 60°, 90°, 110° fan angel

4.Custom Pattern with DOE

In fact, with DOE, Laserland can make any kind of pattern according to clients’ requirements, other than dot, line, or cross-hairs.