With the rapid development of laser equipment in recent years, the laser equipment supporting industry has also shown a booming development trend. The laser head is also one of the core components of laser cutting machines and laser welding machines.

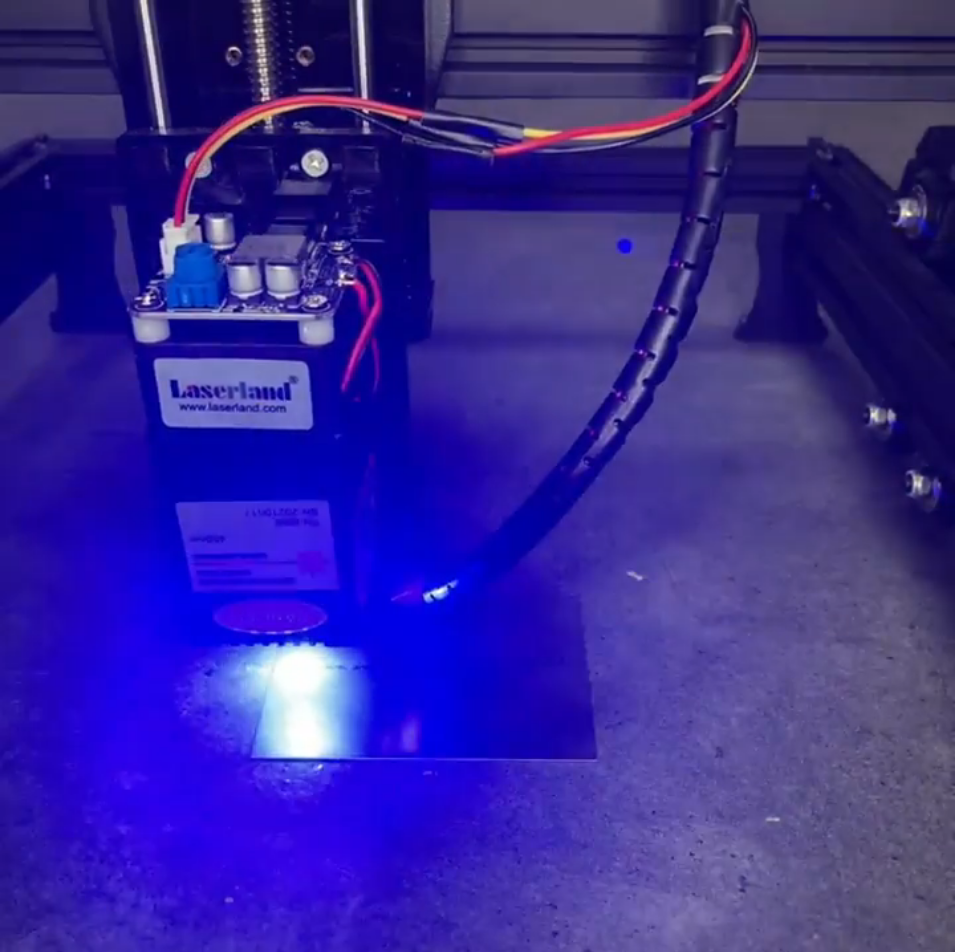

Small and mini laser heads are also composed of laser light source emitters, optical lenses, heat dissipation systems, control circuits, external circuits, etc. The small laser head directly uses a laser diode as the laser light source emitter, which is a semiconductor laser. The size of the laser diode is small, the light output power is ideal, and the engraving effect is better. The small laser head has a small appearance and is simple and convenient to use. Compared with industrial engraving laser heads, small laser heads prioritize appearance size and use small-size laser diodes to achieve greater engraving power while maintaining small size. Small laser engraving machines generally use blue light engraving lasers. It uses a semiconductor laser diode as a laser source to produce a high-energy blue laser beam to cut and engrave the surface of the object. Blue lasers have shorter wavelengths and therefore higher energy density. This makes it have better cutting and engraving effects on certain materials, especially for some materials with higher hardness, such as glass, ceramics, etc.

The application of small laser heads in laser cutting, welding and popular robots is closely related. The cost of a laser welding robot production line is very high, and the laser head is one of its core accessories. This means that there is huge market potential for small laser heads.